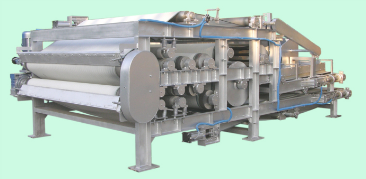

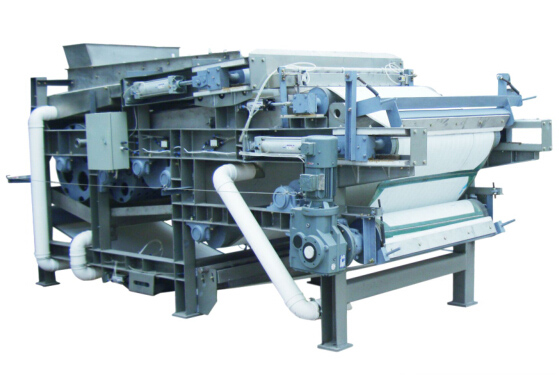

Equipment principle

The DY type belt press filter consists of a gravity dewatering section, a pressing section (with several rollers of different diameters), and upper and lower filter belts. The material is mixed thoroughly with flocculant and enters the flocculation mixer for reaction before flowing into the gravity pre dehydration section; The material is filtered under the action of gravity. The material that has undergone two pre dehydration processes moves forward continuously with the upper and lower filter belts (driven by a transmission mechanism controlled by a frequency converter), and first enters the "wedge-shaped" pressing section: in the "wedge-shaped" pressing, on the one hand, the material is flattened, and on the other hand, it is subjected to mild pressure to dehydrate the material; Next, it enters the "S" - shaped pressing section, where the material is sandwiched between the upper and lower layers of filter belts and repeatedly pressed by several rollers of different diameters to form a shear effect on the material, resulting in dehydration. The dehydrated filter cake is scraped off by a scraper, while the upper and lower filter cloths continue to move forward and enter the next working cycle after cleaning. The entire process repeats itself in a continuous cycle.

|

Specification parameters of BP belt filter press |

||||||||||||||||

|

Width of Filter tray |

500-2000 |

2500-3000 |

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

||||||||

|

Filtering lenght(mm) |

N |

L |

N |

L |

Filtering Area(㎡) |

Weight (kg) |

Filtering Area(㎡) |

Weight (kg) |

Filtering Area(㎡) |

Weight (kg) |

Filtering Area(㎡) |

Weight (kg) |

Filtering Area(㎡) |

Weight (kg) |

Filtering Area(㎡) |

Weight (kg) |

|

3000 |

1 |

8125 |

1 |

8150 |

1.50 |

3100 |

3.00 |

3700 |

4.50 |

4300 |

6.00 |

4900 |

7.50 |

5700 |

9.00 |

6300 |

|

4500 |

2 |

9625 |

2 |

9650 |

2.25 |

3250 |

4.50 |

3890 |

6.75 |

4525 |

9.00 |

5160 |

11.25 |

6000 |

13.50 |

6640 |

|

6000 |

3 |

11125 |

3 |

11150 |

3.00 |

3400 |

6.00 |

4080 |

8.00 |

4750 |

12.00 |

5420 |

15.00 |

6300 |

18.00 |

6980 |

|

7500 |

4 |

12625 |

4 |

12650 |

3.75 |

3550 |

7.50 |

4270 |

11.25 |

4900 |

15.00 |

5680 |

18.75 |

6600 |

22.50 |

7320 |

|

9000 |

5 |

14125 |

5 |

14150 |

4.50 |

3700 |

9.00 |

4460 |

13.50 |

5050 |

18.00 |

5940 |

22.50 |

6900 |

27.00 |

7660 |

|

10500 |

6 |

15625 |

6 |

15650 |

5.25 |

3850 |

10.50 |

4650 |

14.75 |

5275 |

21.00 |

6200 |

26.25 |

7200 |

31.50 |

8000 |

|

A |

400 |

400 |

400 |

400 |

400 |

N400 |

||||||||||

|

B |

3500 |

3500 |

3500 |

3500 |

3500 |

3500 |

||||||||||

|

C |

3000 |

3000 3000 |

3000 |

3000 3000 |

3000 |

3000 3000 |

||||||||||

|

D |

2300 |

2300 |

2300 |

2300 |

2300 |

2300 |

||||||||||

|

E |

1150 |

1650 |

2150 |

2650 |

3200 |

3700 |

||||||||||

|

Fmax |

2150 |

2650 |

3150 |

3650 |

4150 |

4650 |

||||||||||

|

G |

795 |

795 |

795 |

795 |

795 |

795 |

||||||||||

|

Hmax |

1205 |

1205 |

1205 |

1205 |

1205 |

1205 |

||||||||||

|

I |

2200 |

2200 |

2200 |

2200 |

2200 |

2200 |

||||||||||

|

J |

2600 |

2600 |

2600 |

2600 |

2600 |

2600 |

||||||||||

|

K |

1350 |

1850 |

2350 |

2850 |

3350 |

3850 |

||||||||||

|

M |

1300 |

1300 |

1300 |

1300 |

1300 |

1300 |

||||||||||

|

R |

1250 |

1250 |

1250 |

1250 |

1350 |

1350 |

||||||||||

|

S |

1450 |

1950 |

2450 |

2950 |

3450 |

3950 |

||||||||||

|

T |

1520 |

1520 |

1520 |

1520 |

1600 |

1600 |

||||||||||

3.png)

1.png)

DF陶瓷过滤机.png)

图片3.png)

图片5.png)

图片2.png)