Advantages and characteristics: High crushing efficiency, long service life, and low replacement cost.

Applicable materials: Black metal, non-ferrous metal ore, limestone, basalt, various metal ores, non-metallic ores, etc.

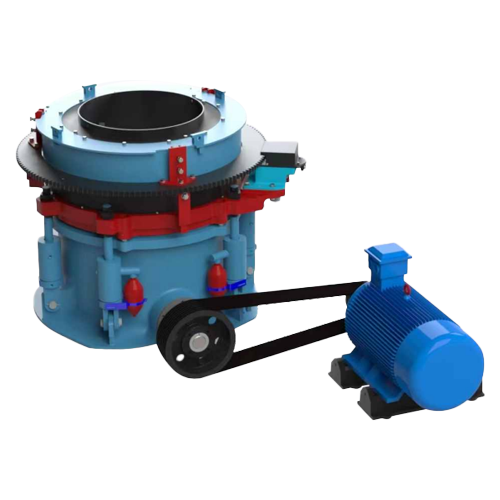

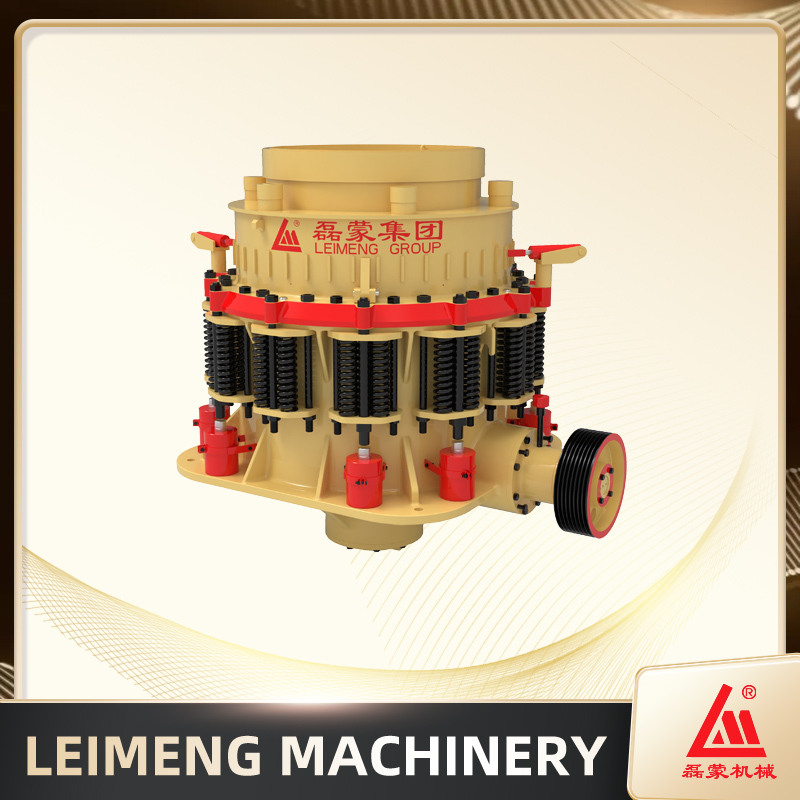

Product introduction

● HPY series multi cylinder hydraulic cone crusher produced by Leimeng is equipped with a safety oil cylinder, a locking oil cylinder, and an automatic adjustment device for the discharge port, achieving functions such as automatic locking and cavity cleaning, reducing adjustment and downtime.

● HPY series multi cylinder hydraulic cone crusher adopts advanced crusher design technology, with high crushing efficiency, high degree of automation, and more importantly, it solves common concerns about output, product particle shape, particle size content, production and maintenance costs, and applicability.

● HPY series multi cylinder hydraulic cone crusher is widely used in mining, metallurgy, sand and gravel, cement and other operations. From black metal ore to non-ferrous metal ore, or limestone and basalt, it is suitable for various metal and non-metal ore crushing, medium fine crushing, and fine crushing operations, especially in fine and ultra fine crushing operations, with outstanding performance.

Structural characteristics

● The equipment adopts high-strength integral casting frame, which has a long service life and high reliability.

● The hydraulic motor adjusts the discharge port, which can achieve remote and accurate continuous adjustment of the discharge port size, making it convenient and fast.

● The crushing chamber adopts the high-efficiency laminated crushing principle, which improves the crushing efficiency and reduces the wear of vulnerable parts. The material is polygonal and has a high content of fine particles

● The assembly surfaces of the rolling mortar wall and the crushing wall are specially designed and precision processed, making installation convenient. The lining plate installation does not require fillers, resulting in low replacement costs and faster replacement.

● The adjustment sleeve locking adopts multiple built-in small hydraulic cylinders for locking, with even force and reliable locking.

● The equipment adopts multiple protections such as labyrinth and spherical floating seals, which are more reliable and have good dust prevention effects.

● The equipment is equipped with hydraulic safety and cavity cleaning functions, which are safe and reliable, and more time-saving and labor-saving.

● The transmission system adopts spiral bevel gear transmission, with strong load-bearing capacity, smooth transmission, and low noise.

● Adopting an automated intelligent control system and an integrated hydraulic lubrication system.

Technical parameter

|

Model |

Maximum feeding size(mm) |

Discharge port size(mm) |

Processing capacity(t/h) |

Motor power(kW) |

|

HPY200 |

185 |

13 |

120~250 |

160 |

|

HPY300 |

230 |

13 |

150~440 |

220 |

|

HPY400 |

300 |

13 |

185~630 |

315 |

|

HPY500 |

330 |

16 |

280~790 |

400 |

|

HPY800 |

350 |

16 |

385~1200 |

630 |

|

Crusher production capacity |

||||||||||

|

Tight edge discharge port |

||||||||||

|

Model |

Unit |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

45mm |

51mm |

|

HPY200 |

t/h |

120-150 |

140-180 |

150-190 |

160-200 |

170-220 |

190-235 |

210-250 |

|

|

|

HPY300 |

t/h |

150-185 |

180-220 |

200-240 |

220-260 |

230-280 |

250-320 |

300-380 |

350-440 |

|

|

HPY400 |

t/h |

185-230 |

225-280 |

255-320 |

275-345 |

295-370 |

325-430 |

360-490 |

410-560 |

465-630 |

|

HPY500 |

t/h |

|

280-350 |

320-400 |

345-430 |

365-445 |

405-535 |

445-605 |

510-700 |

580-790 |

|

HPY800 |

t/h |

|

385-500 |

435-545 |

470-600 |

495-730 |

545-800 |

600-950 |

690-1050 |

785-1200 |

多缸液压圆锥破碎机.png)

多缸液压圆锥破碎机.png)

多缸液压圆锥破碎机多缸圆锥破4.png)

多缸液压圆锥破碎机多缸圆锥破1.png)