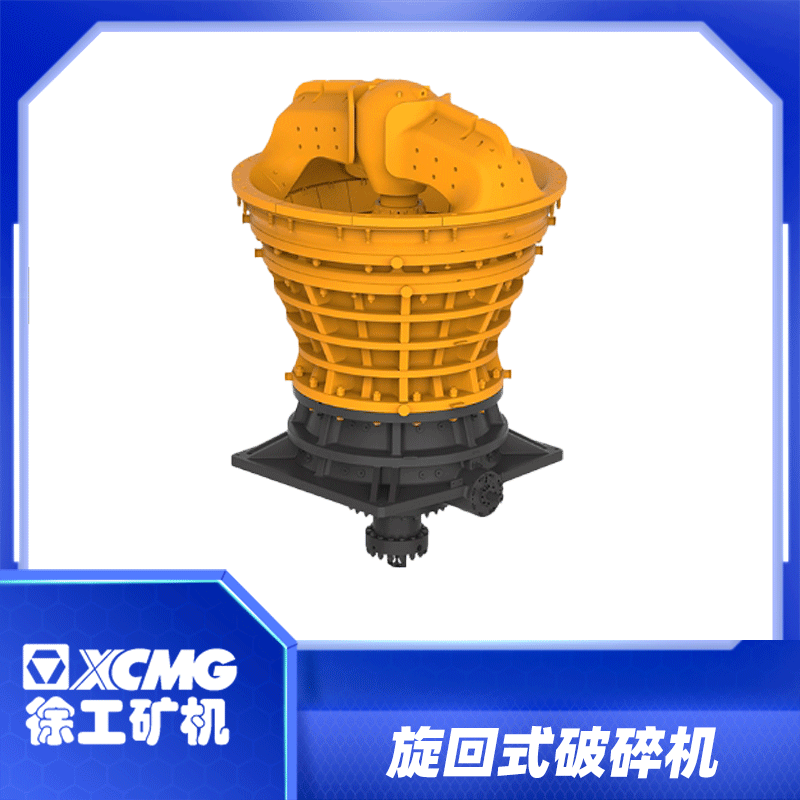

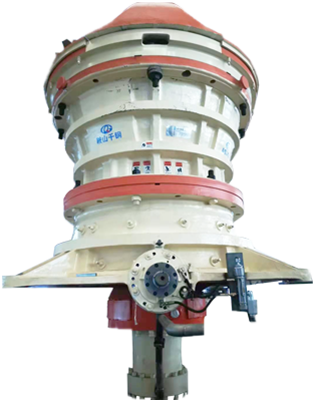

Product Introduction

XH Ratory Crusher can benchmark against internationally advanced gyratory crusher technology and is a new type of intelligent, efficient, and high-capacity coarse crushing equipment. Compared with traditional gyratory crushers, XH gyratory crushers have high crushing efficiency, low cost, and easy maintenance, providing users with efficient and intelligent solutions for ultra large capacity coarse crushing.

Main features: Integrating mechanical, hydraulic, electrical, automation, intelligent control and other technologies.

Application scope: Metallurgical industry, construction industry, road construction industry, chemical industry, silicic acid industry

Materials: dolomite, granite, basalt, diabase, limestone, iron ore, manganese ore, gold ore, copper ore, etc.

Main advantage

l Large production capacity and low cost

The key to the production capacity of equipment lies in the cavity design of the equipment. The XH gyratory crusher has a refined crushing cavity design to ensure stronger production capacity, larger feed particle size, and longer liner life; The stroke and speed of the crusher are optimized through the use of a large inclination angle and a long crushing surface design, which gives it stronger crushing capacity and is suitable for various coarse crushing operations; By simply replacing the eccentric sleeve, the processing capacity of the crusher can be changed to meet different crushing process requirements.

l Continuous high strength

The XH gyratory crusher has a super heavy frame, a large-diameter integral spindle, and high-precision cast bearings, which provide higher overall strength and longer service life, ensuring safer and more reliable continuous high-intensity production; High strength and ultra heavy rack design ensures safe and trouble free operation; The spindle and dynamic cone are forged as a whole to avoid the dynamic cone being used in harsh production conditions, loosening, and reducing downtime during use; The locking thread of the dynamic cone is located on the replaceable spindle sleeve, which has no grooves or stress concentration on the spindle and higher strength.

l Simple operation and maintenance

As a super large equipment, the XH gyratory crusher pays special attention to the convenience of maintenance during design, and is equipped with an automatic lubrication and hydraulic system. The lubrication system can automatically lubricate, heat, cool, and circulate according to production conditions; Configure an automatic spindle position control system that can control the spindle through a hydraulic system, making it easy to adjust the size of the ore discharge port. It can also compensate for liner wear and control product particle size; The gear backlash can be easily adjusted through an external gear adjustment device, and the crossbeam bushing and seal can be replaced without removing the crossbeam. When dismantling the crossbeam, a hydraulic crossbeam separator can be configured.

l Efficient and intelligent production process

The equipment adopts an automated control system, equipped with various sensors such as lubrication pressure, lubrication temperature, bearing temperature, speed, spindle position, etc. It is also equipped with PLC and touch screen to detect and control each link of the equipment and display it in real time; And it can automatically diagnose operational faults and record equipment production information. Automated control systems can not only control and protect equipment operation, reduce equipment maintenance costs and downtime, but also improve equipment efficiency; It can also optimize the working parameters of equipment according to its operating conditions, improve equipment production efficiency, and ensure stable, efficient, and low consumption production of equipment.

Product parameters

|

Model |

Feed Port (mm) |

Outlet(mm) |

Upper Limit Feeding(mm) |

1300 Output(t/h) |

Electric Power(kW) |

|

XH4265 |

1065 |

140-175 |

900 |

2010-2875 |

400 |

|

XH5065 |

1270 |

150-175 |

1050 |

2400-2940 |

400 |

|

XH5475 |

1370 |

150-200 |

1150 |

2890-3490 |

450 |

|

XH6275 |

1575 |

150-200 |

1350 |

2890-4330 |

450 |

|

XH6089 |

1525 |

165-230 |

1300 |

4200-5800 |

630 |

|

XH60110 |

1525 |

175-250 |

1300 |

5530-8890 |

1250 |

2bb96026-e7dd-4531-9537-f0ceab896f84微信图片_202203021553094.png)

PX旋回破√.png)

lQDPJxao3EKSoEvNA3bNB4CwQanrU4panT4DFbonGYAGAA_1920_886.png)

6.png)