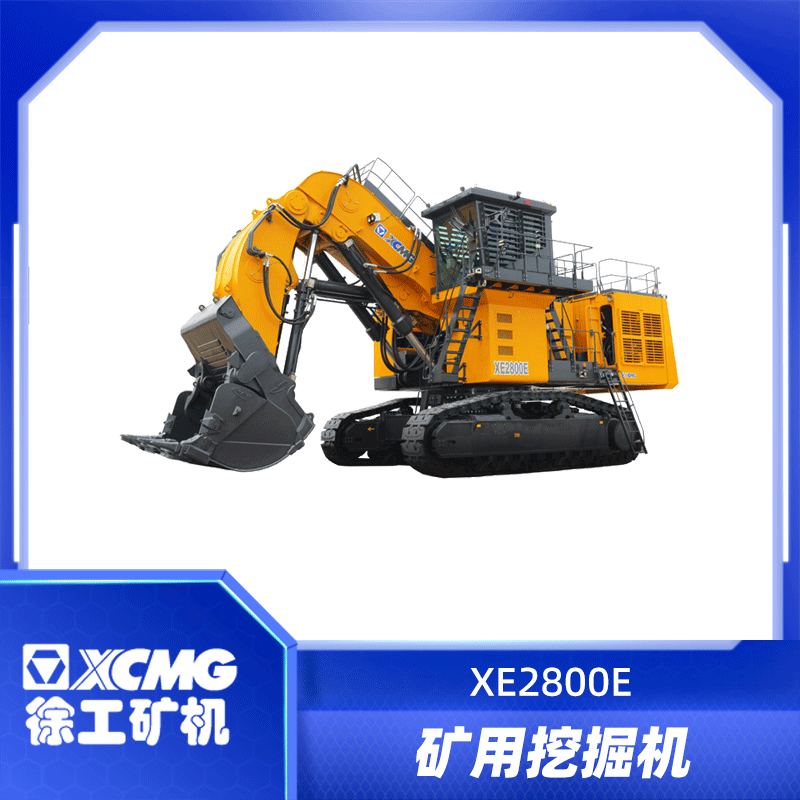

Product selling points

1. The new generation of 95 ton mining hydraulic excavators adopts original imported high horsepower engines, meeting the emission standards of China IV stage, North America Tier 4F, and Europe Stage V. They have the characteristics of strong power, low noise, low fuel consumption, and low emissions; Adopting an electronic control unit pump fuel system suitable for the Chinese market greatly reduces engine failure rates.

2. Optimize the configuration of key hydraulic components, adopt a larger diameter and pressure main valve, an integrated output mechanism rotary reducer, and a larger specification walking reducer, so that the XE950G has greater hydraulic energy, greater rotary and walking driving force, and is more suitable for harsh mining construction.

3. Equipped with a 6-way large capacity rock bucket as standard, it has higher operational efficiency.

4. Adopting advanced electronic control positive flow system greatly improves operational sensitivity and intelligence level.

5. The heat dissipation system adopts dual pump independent control heat dissipation technology, which is more energy-efficient and noise reducing.

6. Adopting a new generation of positive pressure cab, it has high strength, good comfort, integrated intelligent interface, and meets the needs of high-end users.

7. Strengthen the load-bearing capacity of the longitudinal beam and H-frame in the four wheel area of the vehicle, strengthen the track chain, support wheels, etc., and significantly improve the load-bearing capacity; The working device has undergone stress analysis and fatigue testing using a lightweight box structure design, ensuring sufficient strength and stiffness of the structural components. Through rigorous impact testing, the average stress is reduced by 30% compared to XE900D, which can meet the needs of heavy-duty excavation and mining.

8. Increase the thickness of weak areas in the rotary platform, boom, and bucket, which increases the bearing capacity by 50% compared to XE900D and greatly improves the bending section modulus.

9. Adopting a single line electric centralized lubrication system, the lubrication cycle is accurate, and the quantitative grease supply is precise, avoiding the omission of lubrication points during manual greasing and saving human labor intensity.

Product parameters

|

Project |

Unit |

Parameter |

|

Operating weight |

kg |

91000 |

|

Engine power |

kW/rpm |

447/2000 |

|

Bucket capacity |

m³ |

4.6-7 |

|

Maximum stick digging force |

kN |

370 |

|

Maximum bucket digging force |

kN |

463 |

|

Running speed |

km/h |

4.0/2.4 |

|

Rotation speed |

r/min |

6.2 |

|

Maximum digging radius |

mm |

12660 |

|

Maximum dumping height |

mm |

7990 |

Why choose us

Good quality and good service

Dedicated to your exclusive commitment of millions of choices

- SUFFICIENT SUPPLY

- SUPPORT CUSTOMIZATION

- FAST DELIVERY

- RELIABLE QUALITY

- BUYER PROTECTION

- INTIMATE AFTER-SALES

矿用液压挖掘机.png)