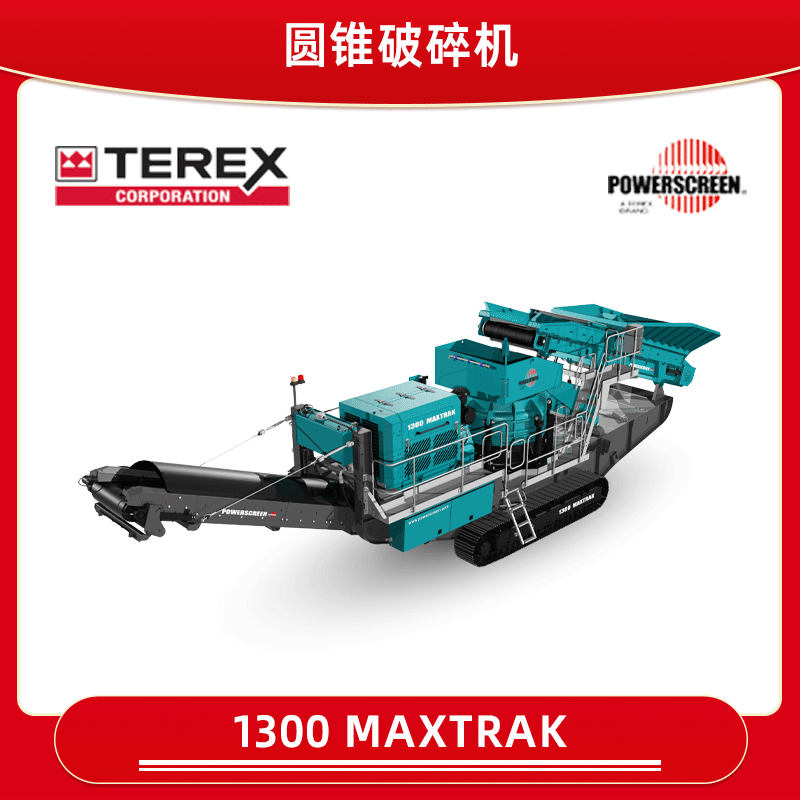

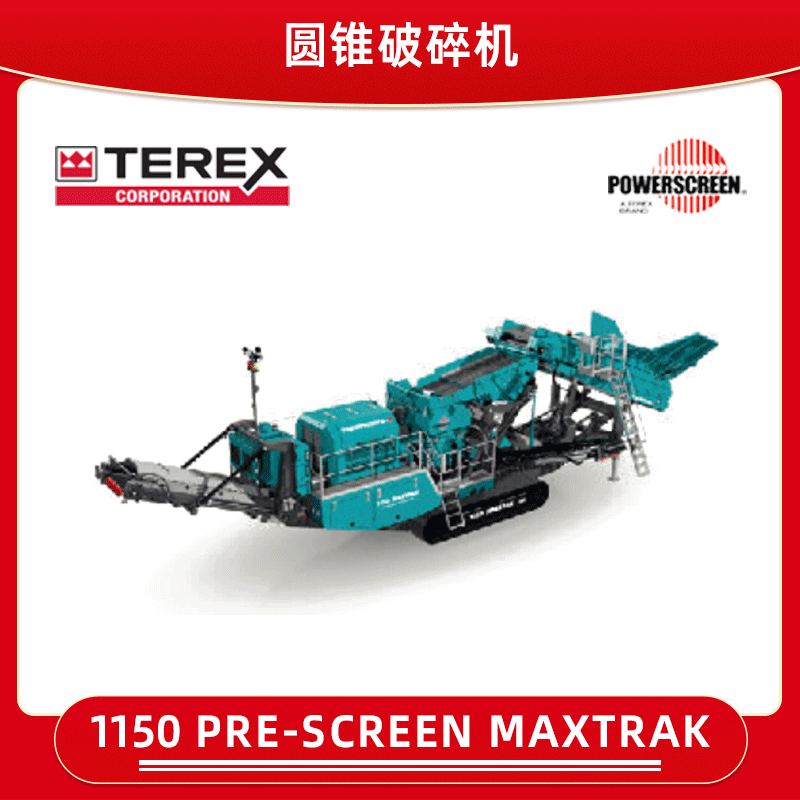

Product Introduction

l Large capacity feeding device ensures smooth material flow and prevents blockage;

l Based on the principle of material lamination crushing and the wear characteristics of the cavity wall, the cavity design is curved to ensure high crushing capacity, high product quality, and low wear costs of the crusher;

l Adjustable eccentricity to adapt to different working conditions and ore requirements;

l The conveyor and hopper are both foldable, making it easy to transfer;

l Wireless remote control, one click start stop, automatic control, intelligent fault diagnosis, overload and over iron protection, real-time monitoring of operating status, menu style touch screen, easy operation;

l Positive pressure dust removal and grounding protection of the control cabinet are safe and reliable;

l Automatic spray dust reduction system;

l The working power source is mains electricity, which can be connected to the external power grid or powered by an external generator set;

l Track chassis: Hydraulic driven tracks+reinforced extended wheelbase+high-low speed switching;

l Frame: High strength alloy steel, suitable for low-temperature environments;

l Conveyor: Driven by an external motor and reducer, maintenance and upkeep are more convenient.

Crawler Mobile Cone Crushing Station Product Series

|

Parameter Name |

Unit |

ZMC300 |

|

Processing Capacity |

t/h |

115-320 |

|

Maximum Feeding Particle Size |

mm |

211 |

|

Main Skin Band width x length |

mm |

B1000×12500 |

|

Discharge height |

mm |

3000 |

|

Specification of sieve holes for return material screening |

mm |

32 |

|

Size of the return material sieve surface |

mm |

3300×1600 |

|

Host power |

kW |

250 |

|

Installed power |

kW |

321 |

|

Engine power |

kW |

103 |

|

Transportation status, external dimensions, length x width x height |

m |

18.1×3.7×3.9 |

|

Total Quality |

t |

54 |

|

Drive form |

\ |

Electric drive |

Note:

1、The walking drive of the track moving cone crushing station is diesel hydraulic drive, and the working drive is external mains power or a complete set of external generator sets connected to the jaw crushing station and screening station.

2、The sieve hole specifications in the table are standard, and other specifications can be selected according to requirements.

履带移动圆锥式破碎站.png)

矿用一体式钻机.png)

矿用分体式钻机.png)

矿用液压挖掘机.png)

矿用液压破碎锤.png)

矿用自卸车.png)

新能源矿用自卸车.png)

履带移动颚式破碎站.png)

履带移动反击式破碎站.png)

履带移动筛分站.png)