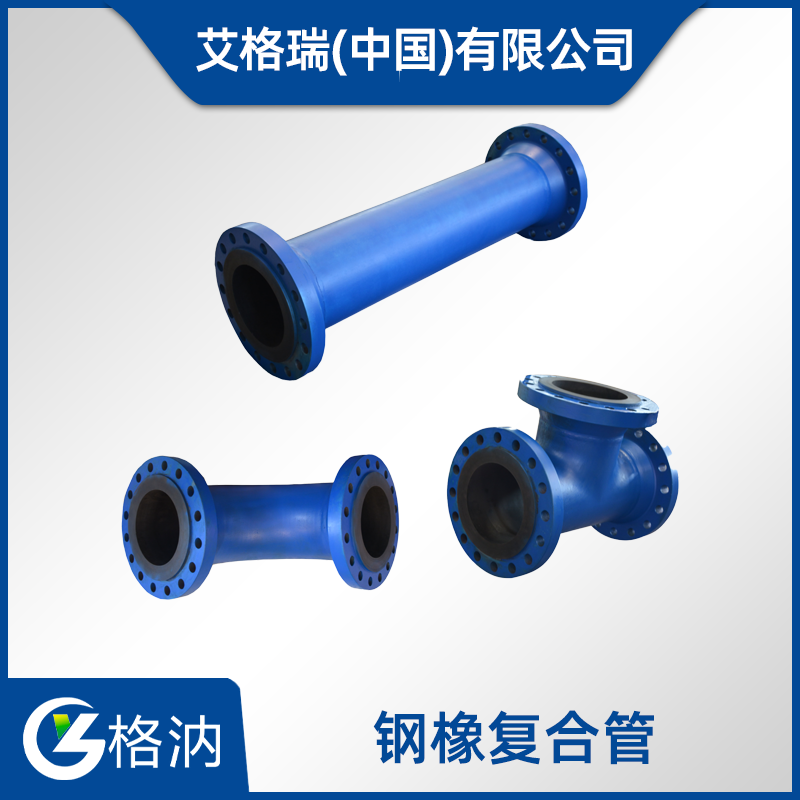

Rubber-lined pipe is an external steel or hard structure as the pipe skeleton, lining wear, corrosion resistance and high temperature resistance rubber as the liner layer, through rubber own physical and chemical properties to reduce the role of pipeline transport media on the external structure such as impact, corrosion and so on, the rubber buffer, greatly prolongs the service life of the pipeline, and reduces the user cost.

1. the structure is excellent

The reinforced skeleton steel pipe and rubber layer using high performance adhesive composite as a whole, overcome the steel pipe withstand not wear resistance, plastic, rubber wear resistance and glass fiber reinforced glass brittle impact resistance and other shortcomings, at the same time with the common advantages of steel tube and wear rubber, comprehensive cost-effective.

2. high strength and high impact resistance

Rubber elastomer has low density, light weight, good vibration absorption performance and excellent mechanical shock resistance, high strength, good rigidity, no creep, anti-impact, anti -seismic, strong resistance to water hammer, easy to transport, installation and maintenance.

3. wide range of temperature adaptation

The desulfurized rubber lining pipe can be used for a long time in the range of-50c ~ +150c, and the rubber lining layer will not be separated from the steel frame due to temperature change.

4.energy-saving

Good lubrication, low running resistance loss and saving running cost.

5.Excellent aging resistance, under normal pressure and temperature, the general service life of more than 15 years(theoretical value). After 6-8 years of use, the pipe will be rotated nearly 90 degrees, the service life will be longer, and the rubber lining pipeline can be used repeatedly 4 times, the cost will be reduced, the production cycle will be short, and the construction period can be guaranteed.

SPC耐磨碳化硅材质.png)

SPB耐磨陶瓷复合材质1.png)

聚氨酯.png)

SPT耐磨高铝陶瓷材质.png)

微信截图_20221013152842.png)