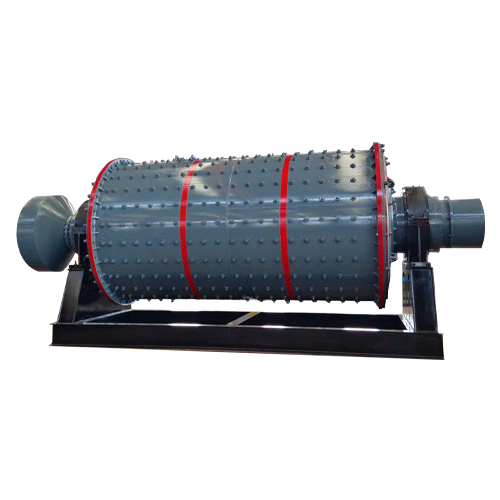

This machine can apply to the local metallurgical, colored mill run, chemical, cement, corharts, glass and building materials industries, such as the grinding of raw materials or finished products.

Ball mill, rod mill grinding, and other equipment are collectively named grinding machine. According to different users’ requirements, we produce plant-based grid, the overflow type, ordinary type (bearing type), energy-saving (bearing type), traction type, center drive, standard type, extended-models and other different specifications, such as wet grinder, dry ball (rod) mill. We also can be based on the requirements of users and produce completed steel frame structure.

The mill produced in our factory now are using double-row spherical roller to replace the traditional Babbitt sliding bearings to reduce the frictional resistance and static resistance torque, so as to achieve energy-saving purpose.

According to the direction of rotation, ball (rod) mill divided into sinistrality and dextrorotation. Facing the discharge hole and rotating clockwise is the dextrorotation, and rotating counter-clockwisly is sinistrality. When ordering goods, please state the direction of rotation. Instructions of model and specifications.

THE MAIN MODELS AND TECHNICAL PARAMETERS OF MQG(Y) BALL MILL:

|

Model specification |

Inside path of the shell(mm) |

Length of the shell(mm) |

Rotated speed of the shell(r/min) |

Max load of rod(t) |

Granularity of feeding(mm) |

Capacity(t/h) |

Motor(kw) |

Speed reducer |

The weight of core(t) |

Outside measurement (L×W×H)(mm) |

|

MQG0613 |

650 |

1300 |

52 |

0.8 |

0-20 |

0.2-0.8 |

5.5 |

- |

2.8 |

2100×1785×1070 |

|

MQG0718 |

700 |

1800 |

45 |

1 |

0-20 |

0.3-1.1 |

7.5 |

- |

3.5 |

3120×1555×990 |

|

MQG0818 |

800 |

1800 |

42.5 |

1.4 |

0-20 |

0.4-1.6 |

11 |

- |

4.5 |

3120×1555×990 |

|

MQG0918 |

900 |

1800 |

39 |

1.9 |

0-20 |

0.5-2.2 |

18.5 |

ZD20 |

5.7 |

5080×2280×2020 |

|

MQG0924 |

900 |

2400 |

41 |

2.6 |

0-20 |

0.7-2.9 |

30 |

ZD25 |

5.94 |

5750×2330×2020 |

|

MQG1224 |

1200 |

2400 |

36.7 |

4.4 |

0-25 |

1.5-5 |

45 |

ZD30 |

13.4 |

6488×2860×2540 |

|

MQG1230 |

1200 |

3000 |

36.7 |

5.5 |

0-25 |

1.5-6.2 |

55 |

ZD30 |

15.5 |

7138×2859×2540 |

|

MQG1530 |

1500 |

3000 |

31 |

8.8 |

0-25 |

3-8 |

90 |

ZD35 |

19 |

7455×3260×2770 |

|

MQG1535 |

1500 |

3500 |

31 |

10.2 |

0-25 |

3.5-9 |

110 |

ZD35 |

20.5 |

7955×3260×2770 |

|

MQG1540 |

1500 |

4000 |

31 |

11.7 |

0-25 |

4-10 |

132 |

ZD40 |

22 |

8525×3310×2770 |

|

MQG1830 |

1830 |

3000 |

29 |

14 |

0-25 |

5-13 |

155 |

ZD45 |

26.5 |

8066×3770×3070 |

|

MQG1835 |

1830 |

3500 |

29 |

16 |

0-25 |

5.8-15 |

185 |

ZD45 |

28 |

8566×3770×3070 |

|

MQG2130 |

2100 |

3000 |

23.6 |

19 |

0-25 |

7-20 |

180 |

ZD60 |

46 |

9346×4912×4285 |

|

MQG2135 |

2100 |

3500 |

23.6 |

22 |

0-25 |

7-23 |

210 |

ZD60 |

50 |

9846×4912×4285 |

|

MQG2436 |

2400 |

3600 |

23.6 |

30 |

0-25 |

9-33 |

320 |

ZDY400 |

62 |

9946×4921×4285 |

|

MQG2445 |

2400 |

4500 |

23.6 |

37 |

0-25 |

10-41 |

380kw |

ZDY400 |

70 |

10846×5021×4285 |

|

MQG2736 |

2700 |

3600 |

21.7 |

41 |

0-25 |

12-40 |

400kw |

- |

79 |

9980×6080×4675 |

|

MQG2745 |

2700 |

4500 |

21.7 |

54 |

0-25 |

12-50 |

500kw |

- |

92 |

10880×6080×4675 |

|

MQG3236 |

3200 |

3600 |

18.5 |

54 |

0-25 |

20-70 |

630kw |

- |

122 |

11600×7200×5700 |

|

MQG3245 |

3200 |

4500 |

18.5 |

65 |

0-25 |

20-80 |

800 |

- |

136 |

13000×7300×5700 |

干式球磨机.png)

彬州恒达-高效浓缩机.png)

圆盘给料机.png)

轻型板式给料机.png)

干式球磨机.png)